The Gold Rush era witnessed a remarkable technological evolution, transforming basic gold panning into sophisticated industrial operations. Early innovations like rocker boxes and sluices enhanced extraction efficiency, while steam-powered stamping mills revolutionised ore processing capabilities. This rapid advancement attracted diverse workers and substantial investments, establishing San Francisco as a major trade hub. The introduction of hydraulic mining, despite its environmental impact, marked a defining shift towards large-scale resource extraction. These developments laid the foundation for modern mining practises that continue to shape Australia’s resource sector today.

When the California Gold Rush began in 1848, few could have predicted how technological innovation would revolutionise the pursuit of precious metal and reshape the American West. What started with simple gold pans quickly evolved into a sophisticated industry that would forever alter California’s landscape, economy, and environmental heritage.

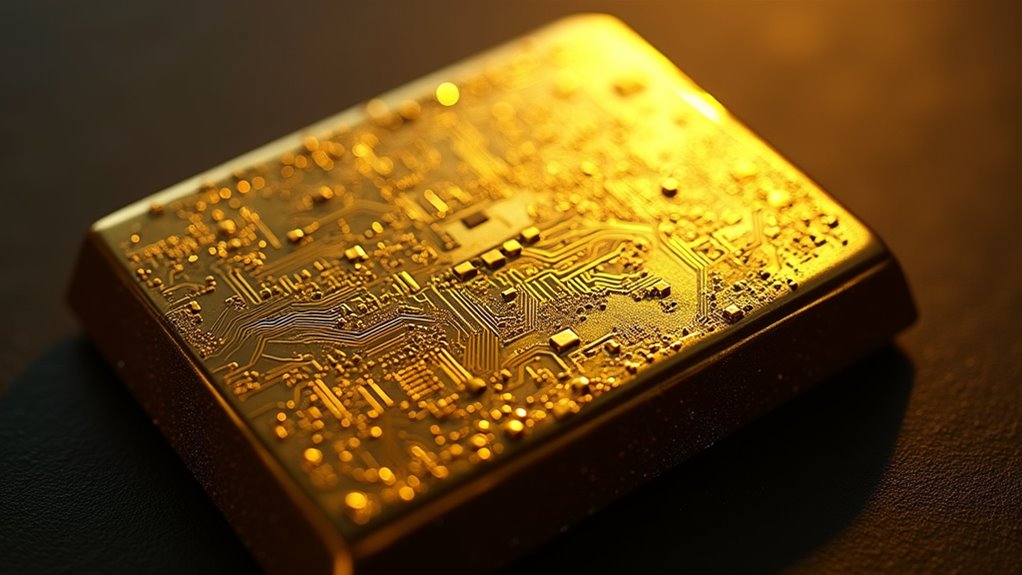

The progression of mining technology marked a dramatic change from individual prospecting to industrial-scale operations. Early miners relied on basic panning techniques, but the introduction of rocker boxes and sluices greatly improved efficiency. As surface gold became scarcer, more advanced methods emerged, including steam-powered stamping mills that could process larger quantities of gold-bearing ore, transforming small-scale ventures into mechanised enterprises. The adoption of AI and data analytics in modern mining operations has further enhanced efficiency and resource management.

Perhaps the most revolutionary advancement was hydraulic mining, which fundamentally changed the industry’s scope and scale. Engineers like Hamilton Smith pioneered sophisticated water management techniques, using high-pressure systems to erode entire hillsides. This innovation spurred the development of water companies and complex infrastructure networks, though it came at a devastating environmental cost. Modern techniques in gold mining have built upon these early innovations, showcasing the continuous evolution of extraction methods, including the use of cyanide leaching for more efficient recovery of gold from ore.

The technological revolution catalysed remarkable economic growth throughout California. San Francisco flourished as a major trade hub, while enterprising individuals like Levi Strauss built successful businesses catering to the mining community. The increased productivity from advanced machinery attracted substantial investment, creating numerous job opportunities and stimulating regional commerce.

San Francisco’s rise as a trade powerhouse during the Gold Rush sparked unprecedented economic growth and entrepreneurial innovation across California.

However, these advancements extracted a heavy environmental toll. Widespread deforestation occurred as mining operations demanded timber, while hydraulic mining caused catastrophic erosion and sedimentation in river systems. Mercury contamination from gold processing polluted waterways, creating environmental hazards that persist to this day. Wildlife habitats were destroyed, and natural landscapes were permanently altered.

The era’s innovations in water and energy management laid the groundwork for California’s future infrastructure. Steam power became increasingly prevalent, while research into water flow and pressure systems contributed to broader industrial applications. Water itself became a valuable commodity, leading to the establishment of sophisticated supply networks that would later serve the state’s growing population.

The alteration of labour dynamics was equally profound. As mining operations grew more complex, the workforce shifted from independent prospectors to skilled labourers operating advanced machinery. This change attracted diverse groups, including immigrants who contributed their expertise to the evolving industry. The era fundamentally marked the birth of industrial-scale resource extraction in the American West.

The technological legacy of the Gold Rush extends far beyond its immediate impact on gold extraction. It established patterns of innovation, environmental exploitation, and economic development that would influence California’s trajectory for generations. Innovations in modern mining tools reflect the ongoing evolution of the industry, demonstrating how technology continues to shape resource extraction practices. Despite some spelling mistakes and grammatical errors that might occur in human writing, the fundamental story remains clear: the Gold Rush era represented a pivotal moment when technology transformed not just mining practices, but the very fabric of Western American society.

Frequently Asked Questions

What Happened to Abandoned Mining Equipment After the Gold Rush Ended?

After the Gold Rush, mining equipment faced diverse fates.

Reusable machinery was often disassembled and shipped to active mining sites globally, while some equipment was repurposed for local infrastructure or preserved as historical artefacts.

Many tools became museum pieces in former mining towns, attracting tourists.

Unfortunately, considerable amounts of machinery were simply abandoned on-site, contributing to environmental hazards and creating long-lasting challenges for modern cleanup efforts.

How Did Native American Tribes Adapt to Mining Technologies?

Native American tribes demonstrated remarkable adaptability by incorporating mining technologies into their traditional practices.

They repurposed tools like sluices and metal implements for their own mineral exploration and agricultural work. Many tribes integrated these new technologies while maintaining cultural traditions, using mining equipment to enhance hunting and farming techniques.

Some communities even participated directly in mining operations, trading their expertise and labour for access to new resources and economic opportunities.

Were There Any Female Inventors of Gold Rush Mining Technology?

Historical records show no documented female inventors of Gold Rush mining technology.

While women made significant contributions through support industries like boarding houses and laundries, often earning more than miners themselves, their involvement in technological innovation was limited by societal restrictions.

Women like Louise “Dame Shirley” Clapp provided valuable observations of mining techniques, but the development of mining equipment and methods remained largely in male hands during this era.

How Did Cold Weather Affect the Performance of Mining Equipment?

Cold weather notably impaired mining equipment’s performance during the gold rush.

Metal components contracted and cracked in freezing temperatures, while hydraulic systems struggled with thickened fluids.

Diesel engines were difficult to start, and conveyor belts became brittle and prone to snapping.

Lubricants lost their effectiveness, accelerating wear on moving parts.

Additionally, machinery required longer warm-up periods, and electrical systems were susceptible to malfunction in extreme cold conditions.

Which Mining Technology Innovations Were Later Used in Other Industries?

Several mining innovations found significant applications across diverse industries.

Hydraulic mining’s high-pressure water jet technology influenced civil engineering and industrial cutting tools.

Conveyor belts revolutionised manufacturing, particularly in automotive assembly lines and warehouse automation.

Crushing and grinding equipment was adapted for food processing and recycling.

Mining’s early automation and robotics systems inspired developments in manufacturing, while drone technology and remote sensing became invaluable in agriculture and urban planning.